Material

Material: SS 201, SS304, SS304L, SS316, SS316L, SS321, SS347,SS430, Monel. Type 304 Often referred to as "18-8" (18% chromium, 8% nickel) T-304 is the basic stainless alloy most commonly utilized for wire cloth weaving. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 1400 Degrees Fahrenheit. Type 304 L Type 304 L is very similar to T-304, the difference being the reduced carbon content for better weaving and secondary welding characteristics. Type 316 Stabilized by the addition of 2% molybdenum, T-316 is an "18-8" alloy. Type 316 has better resistance to pitting corrosion than the other chromium-nickel stainless steels where brines, sulphur-bearing water or halogen salts, such as chlorides are present. A valuable property of T-316 is high creep strength at elevated temperatures. Other mechanical properties and fabricating characteristics are similar to T-304. Wire cloth woven of T-316 has extensive use in chemical processing when better corrosion resistance is required than the regular chromium-nickel types. Type 316 L Type 316 L is very similar to T-316, the difference being the reduced carbon content for better wire cloth weaving and secondary welding characteristics.Specification

| Specification List of Stainless Steel Wire Mesh | ||

| Mesh/Inch | Wire Gauge(BWG) | Aperture in mm |

| 3mesh x 3mesh | 14 | 6.27 |

| 4mesh x 4mesh | 16 | 4.27 |

| 5mesh x 5mesh | 18 | 3.86 |

| 6mesh x 6mesh | 18 | 3.04 |

| 8mesh x 8mesh | 20 | 2.26 |

| 10mesh x 10mesh | 20 | 1.63 |

| 20mesh x 20mesh | 30 | 0.95 |

| 30mesh x 30mesh | 34 | 0.61 |

| 40mesh x 40mesh | 36 | 0.44 |

| 50mesh x 50mesh | 38 | 0.36 |

| 60mesh x 60mesh | 40 | 0.30 |

| 80mesh x 80mesh | 42 | 0.21 |

| 100mesh x 100mesh | 44 | 0.172 |

| 120mesh x 120mesh | 44 | 0.13 |

| 150mesh x 150mesh | 46 | 0.108 |

| 160mesh x 160mesh | 46 | 0.097 |

| 180mesh x 180mesh | 47 | 0.09 |

| 200mesh x 200mesh | 47 | 0.077 |

| 250mesh x 250mesh | 48 | 0.061 |

| 280mesh x 280mesh | 49 | 0.060 |

| 300mesh x 300mesh | 49 | 0.054 |

| 350mesh x 350mesh | 49 | 0.042 |

| 400mesh x 400mesh | 50 | 0.0385 |

Woven type available

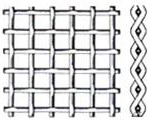

1. Stainless steel wire mesh, plain weave The Plain Wire Cloth Weave is the most common wire cloth used and it is one of the simplest wire cloths. The plain wire cloth is not crimped before weaving, and each warp wire passes over/under the wires running through the cloth at 90 degree angles. 2. Stainless steel wire mesh, twill weave

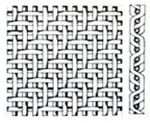

The Plain Wire Cloth Weave is the most common wire cloth used and it is one of the simplest wire cloths. The plain wire cloth is not crimped before weaving, and each warp wire passes over/under the wires running through the cloth at 90 degree angles. 2. Stainless steel wire mesh, twill weave  Each warp and shute of the Twill Square Weave Wire Cloth, is woven alternately over two and under two warp wires. This gives the appearance of parallel diagonal lines, allowing the twill square weave wire cloth to be used with heavier wires with a particular mesh count (that is possible with the plain weave wire cloth). This ability allows the application of this wire cloth for greater loads and finer filtration. 3. Stainless steel wire cloth, plain Dutch weave

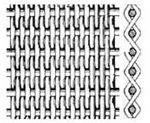

Each warp and shute of the Twill Square Weave Wire Cloth, is woven alternately over two and under two warp wires. This gives the appearance of parallel diagonal lines, allowing the twill square weave wire cloth to be used with heavier wires with a particular mesh count (that is possible with the plain weave wire cloth). This ability allows the application of this wire cloth for greater loads and finer filtration. 3. Stainless steel wire cloth, plain Dutch weave  The Plain Dutch Weave Wire Cloth or wire filter cloth is woven the same way as the plain weave wire cloth. The exception of the plain dutch wire cloth weave is that the warp wires are heavier than the shute wires. 4. Stainless steel wire cloth, twill Dutch weav

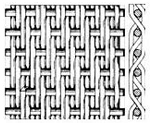

The Plain Dutch Weave Wire Cloth or wire filter cloth is woven the same way as the plain weave wire cloth. The exception of the plain dutch wire cloth weave is that the warp wires are heavier than the shute wires. 4. Stainless steel wire cloth, twill Dutch weav  Our Twilled Dutch Weave Wire Cloth or Wire Filter Cloth, in which each wire passes over two and under two. With the exception that the warp wires are heavier than the shute wires. This type of weave is capable of supporting greater loads than the Dutch Weave, with finer openings than the Twilled Weave. It is used in applications where filtering of heavy material is necessary.

Our Twilled Dutch Weave Wire Cloth or Wire Filter Cloth, in which each wire passes over two and under two. With the exception that the warp wires are heavier than the shute wires. This type of weave is capable of supporting greater loads than the Dutch Weave, with finer openings than the Twilled Weave. It is used in applications where filtering of heavy material is necessary.